Container Camp

ZN House has been designing container camp units worldwide for the mining, oil, and construction industries since 2005. We create living solutions through modular habitats that elevate the comfort level in any harsh natural environment.

The structures we design are certified to ISO standards and manufactured in accordance with CE, UL, and BV standards. They have excellent thermal insulation and integrated MEP (Mechanical, Electrical, and Plumbing) systems. We offer stable and weather-controlled spaces for safety and productivity in the harshest environments of the earth, be it remote drilling sites in highly seismic areas, or fast-deploy construction camps.

Container Camp Project?

We are not mere container shippers; we are environmental engineers.

With over 20 years of experience in industrial engineering and more than 3,000 camp projects in the portfolio, ZN House operates a 7-Stage Integrated Delivery System to guarantee the success of the project.

- Phase 1: Technical Consultation: Site-specific analysis (climate, terrain, and local building codes).

- Phase 2: Custom Engineering: 2D floor plans and 3D modeling tailored to workforce density.

- Phase 3: Precision Manufacturing: Factory-controlled production following ISO 9001 standards for structural consistency.

- Phase 4: Logistics: Global shipping optimization to minimize lead times and freight costs.

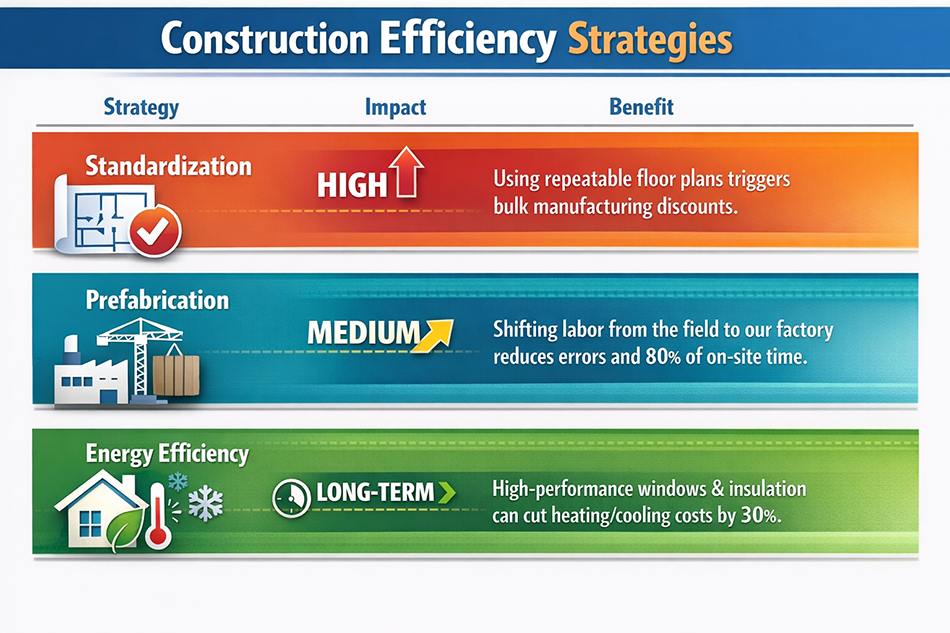

- Phase 5: Rapid Assembly: 'Plug-and-play' design that reduces on-site labor by up to 60%.

- Phase 6: Quality Validation: Rigorous 24-point inspection, including waterproofing and electrical load testing.

- Phase 7: Lifetime Support: Post-installation technical assistance and modular expansion consulting."

Heavy-Duty Mining Camp Solutions

Designed to meet the most challenging requirements of the extractive environments worldwide, ZN House Mining Camps can survive extreme temperature changes (from -30 °C to +55 °C) and are built to resist strong winds typical of open-pit mines.

We offer units with Q355B galvanized steel frames and high-density rockwool insulation (Class A1 fire-rated) to guarantee not only safety but also energy efficiency in hard-to-reach areas. It does not matter if you need a 50-man exploration base or a 1,000-man permanent residence; our modular units are 'Plug-and-Play,' which means that you can quickly continue to develop your site without having to stop the mining operations that are already going on.

Rapid-Deploy Construction Site Camps

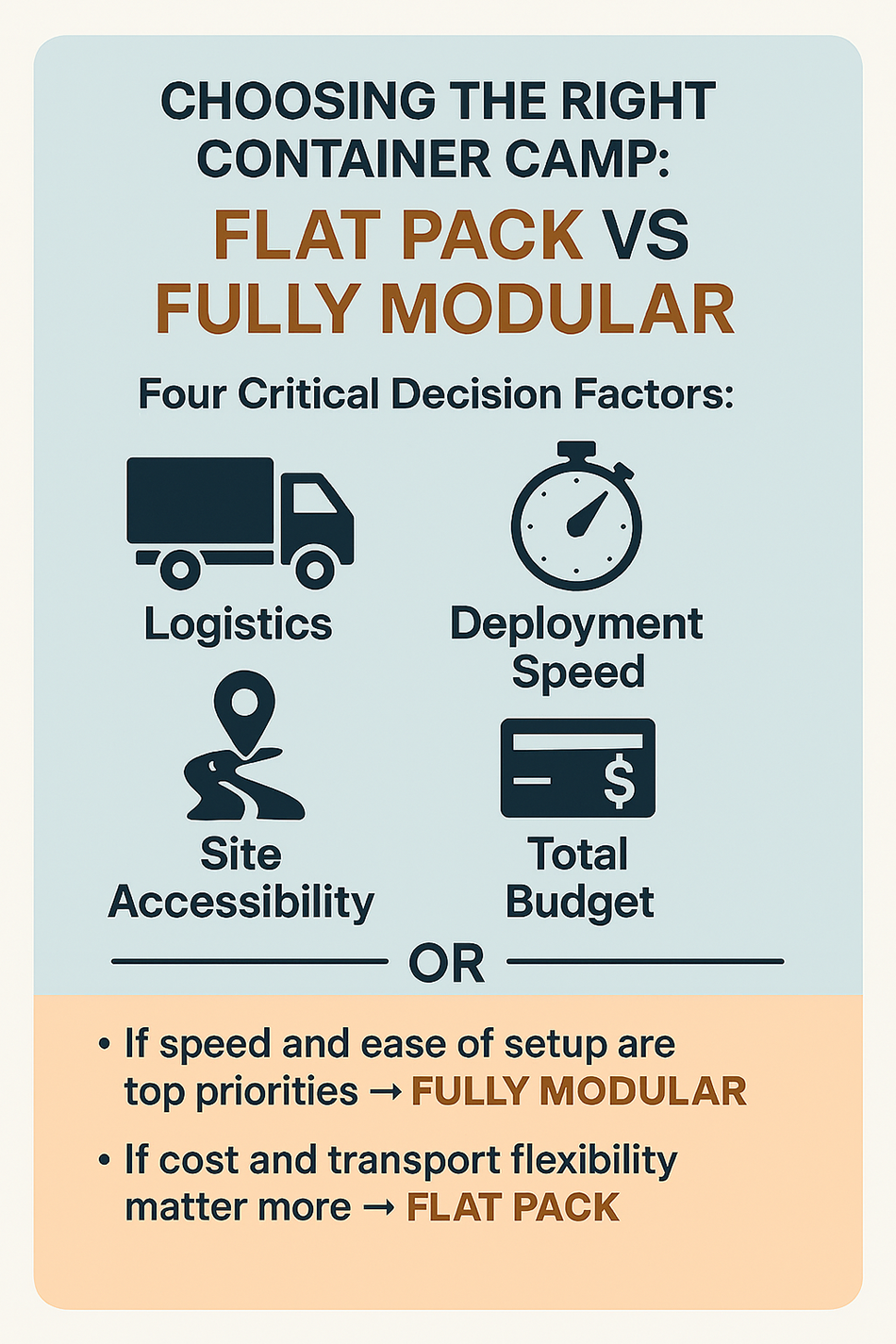

Time is money in the construction business. ZN House Construction Camps offer a high-density, fast-assembly housing solution that can be made available within a few days rather than weeks. By using our modular 'Flat-Pack' or 'Foldable' models, you can have a shipment fully loaded with up to 6 units per 40HQ container, thereby cutting the transport costs of your large-scale infrastructure projects enormously.

These are essentially portable accommodation units for site workers, constructed with easy-to-clean surfaces and made stackable (up to 3 levels) to allow for the smallest of site footprints to be maximized; hence, they are said to be versatile. Moreover, each camp has been designed to facilitate utility connection via 'plug-and-play', thus, the workforce will be lodged and efficient from Day 1.

Rapid-Response Humanitarian Shelters (Refugee Camps)

In emergencies, the time taken to deploy is essentially the number of lives that could be saved. ZN House Refugee Camps are designed to be quickly deployed on a large scale, by means of a foldable or flat-pack configuration that makes it possible for hundreds of units to be transported and set up in less than 48 hours.

Our housing facilities are over and above the minimum standards of the Sphere Project for the humanitarian sector in terms of living space, thus ensuring that the refugees are given a safe, weather-proof environment which, in addition to protection, also provides them with dignity. Every single unit is made out of recyclable and non-toxic materials and is equipped with a high-thermal performance system so as to keep the vulnerable groups away from extreme cold or heat without the need for heavy energy consumption.

Bespoke Modular Environments (Customized Camp)

In cases where standard designs fail to fulfill your operational objectives, ZN House offers complete architectural customization of all kinds. Our engineering team employs cutting-edge BIM (Building Information Modeling) technology to create tailored facilities that merge effortlessly with your current setup.

We not only provide simple housing but also tailor the internal arrangements for:

- Medical & Laboratory Suites: HEPA filtration and anti-microbial surfaces.

- Executive VIP Quarters: Enhanced soundproofing, luxury finishes, and en-suite facilities.

- IT & Command Centers: Built-in server racks, raised flooring, and the cooling system designed for the equipment.

- Commercial Hubs: Modular kitchens, gyms, and recreational laundry blocks.

No matter if you have a specific area or are constrained by nature, we are going to support you with tailor-made CAD drawings and structural calculations so that your one-of-a-kind camp is not only functional but also complies with the local zoning rules.

Why Container Camps are the Future of Global Accommodation

- Comparative Savings: Our modular systems typically reduce initial capital expenditure by 50% or more compared to traditional masonry or timber builds.

- Asset Recovery & Resale: Unlike the conventional "sunk-cost" buildings, ZN units are considered to be highly valuable mobile assets. As such, these units are capable of being taken apart, moved, and reassembled at other project sites, thus sharing the investment across various project lifecycles, since they hold close to 70% of their initial value.

- Low Maintenance Overheads: Long-term upkeep costs are reduced by the use of industrial-grade galvanized steel and high-performance coatings; the structure is thus kept as a viable asset for 25+ years.

- Carbon Footprint: Our modular system reduces CO2 emissions by 60% compared to traditional on-site construction.

- Material Recovery: It is to be noted that every unit is constructed with 95% recyclable materials and is "Solar-Ready," allowing for easy integration of rooftop PV panels to achieve off-grid energy independence.

- Rapid Installation: These units come 90% factory-complete. By means of our patented interlocking systems, it takes only 12 days to level and connect a single unit.

- Vertical Scalability: Designed to meet high-density needs, modular units can be stacked up to 3 stories without the need for extra structural support, thus being perfect for tightly packed urban construction sites or vast mining headquarters.

- Integrated Systems: HVAC, electrical, and plumbing are pre-installed and tested in our factory. This "Plug-and-Play" functionality means that you do not have to employ a specialized on-site contractor.

- Structural Warranty: For permanent or multi-year installations, a long-term structural warranty is included with every modular unit, providing long-term peace of mind.

Container Camp Budgeting: A Strategic Cost Breakdown

The ZN House Advantage: Engineering Global Communities

Office Project

Pre-sales Assistance

After-Sales Service

-

What is the Service Life of a Container Camp Project?

Prefab structures fall into the category of long-lasting buildings, with a safe usage lifespan of approximately 20 years. However, factors such as excessive wind, snow, rain, humidity, and usage conditions can impact their longevity. Like other types of buildings, regular maintenance is necessary to ensure optimal performance.

-

How Are Container Camp Project Prices Determined?

Pricing depends on various factors, including the quality and thickness of the steel structure, the thickness and quality of materials used in the wall panels, roof insulation, and window quality. Additionally, the use of extra materials for enhanced wall and roof insulation can also influence the overall cost. For a free quote, please contact us.

-

How long is the customization cycle for a container camp project?

Typically, the customization of a container camp project takes 10–15 days, depending on the specific requirements of the client. The customization process includes initial communication to understand the needs, layout design, confirmation of the 3D render, factory production, quality inspection, and shipping. Contact us to get your own production schedule!

-

What is the estimated shipping time from our factory to various regions worldwide?

East Asia (Japan, South Korea, Hong Kong, Taiwan): 1 day

Southeast Asia (Singapore, Malaysia, Thailand, etc.): 7 days

South Asia (India, Pakistan, etc.): 15 days

Australia and New Zealand: 20 days

Middle East (Dubai, Iran, and other Arab countries): 15 days

North Africa and the Mediterranean region (Turkey, Spain, Greece, etc.): 25 days

European countries (UK, France, Germany, Italy, etc.): 28 days

East Africa (Sudan, Kenya, South Africa, etc.): Around 25 days

West Africa: 35 days

North America (East Coast and West Coast): East Coast 12 days, West Coast 22 days

Central America: 20 days

South America: 25 days to the West Coast, 30 days to the East Coast -

How much cost can a container camp save compared to traditional temporary buildings?

ZN-HOUSE’s container camp saves 30%-40% in overall costs versus traditional brick-concrete or panel buildings, thanks to prefabricated production and modular design. Factory prefabrication reduces on-site construction time and labor costs, while standardized components minimize material waste. Transport volume is compressed (one 40ft container holds parts for three 20ft camp units), cutting logistics costs further. For a 100-person camp, the container solution costs 150,000 RMB less upfront than traditional options, with 25% lower maintenance costs due to galvanized steel corrosion resistance and self-cleaning wall coatings—making it a cost-effective choice for mid-large projects.

-

How does a container camp ensure living safety and security needs?

Our container camp enhances structural safety and security measures: the main frame uses Q355B high-strength galvanized steel, certified for 12-level wind resistance and magnitude 7 earthquake resistance. Walls and roofs feature fireproof rock wool (fire rating A1 class), with built-in emergency lighting, fire sprinklers, and optional access control systems, surveillance cameras, and fence alarms.

-

Can a container camp be relocated or reused after a project ends?

Yes—container camp modular design supports fast disassembly and off-site reconstruction, with 95% of components reusable. Dismantling a single unit takes just 2 hours, with transport volume reduced by 70% versus assembled size, fitting standard containers. After completing a tunnel project in Southeast Asia, a client disassembled 200 camp units and transported them to the next site, achieving 60% faster reconstruction with no structural degradation. This "build-use-relocate" cycle makes container camps sustainable for long-term projects.

-

How does a container camp maintain livability in extreme climates like high heat or cold?

For extreme environments, our container camp offers customized climate solutions: in tropical regions, exterior walls use reflective thermal insulation coating (reducing indoor temp by 5°C) with ventilation louvers, and bathroom modules have moisture-proof treatment. In cold areas, wall insulation thickens to 100mm (thermal conductivity ≤0.03W/m·K), with optional geothermal systems and double-layer vacuum glass (insulation +40%). A 2023 Alaska oil and gas camp maintained 20°C indoors at -35°C, consuming 30% less energy than traditional temporary buildings—proving adaptability in extreme climates.

Free Consultation

Start Your Personalized Gift Journey

Provide personalized gift customization services, whether it is personal or corporate needs, we can tailor for you. Feel free to contact us for a free consultation!

- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani